One of the machines required by most industries is the grinding machine. Food, chemical, pharmaceutical, cosmetics, livestock and poultry industries and perfumery industries need a grinding machine to powder their desired materials.

Bekordane company is one of the most reliable mill manufacturing factories. This company has different types of mills; It produces home and workshop, etc. for different jobs and uses. In this article, we are going to talk about making a grinding machine, types of grinding, methods of making grinding.

Types of mills

Mills can be classified in different ways, in the following we will examine some of the most important types of mills.

- Cradle mills and tabletop mills: Cradle mills and tabletop mills are known as household mills. These types of mills are the best-selling mills due to their small size, cheapness and ease of use.

- These types of mills are used in small home businesses, ataris, confectioneries, livestock farms, poultry farms, and even for home use. Home mills can finally grind up to 20 kilos in each round.

Semi-industrial mills: Semi-industrial mills that include hammer and sword mills. Semi-industrial mills are used for workshops and cases that require higher volume production. - In fact, instead of adding several machines, they use a semi-industrial mill. Semi-industrial grinding machines have a power of several horsepower, which can work up to 3 thousand revolutions per minute. Semi-industrial mills can powder and grind up to 40 kilos per round.

- Industrial mills: With industrial mills, the entire process of powdering and grinding materials is done by the machine. Fully automatic industrial grinding machines are mostly used for factories and mass production. It can be used to grind spices, food, dry herbs, etc. Industrial mills are designed in different sizes and shapes with different capabilities.

The advantages of industrial mill compared to other mills are:

- The full automaticity of these types of mills.

- When using and pulverizing, materials with an industrial mill emit much less dust than other types.

- With an industrial mill, powdered products are not wasted.

Industrial mills are produced in several designs, including: hammer mills, pin mill mills, gear or propeller curtain mills, cradle mills, ball mills, jet mill mills, air classification mills.

Methods of making a grinding machine

In the construction of the grinding machine, a material must be used that does not corrode, rust, and is not destroyed. Steel 304 or 316 can be the best material for high performance of the grinding machine.

Note that if the body of the grinder is rusted or corroded, corrosion and rust may enter the ground material. The motor used in the mill should be according to the capacity of the machine. The higher the engine power, the greater the capacity of the machine for grinding. Of course, the type of motor and the brand of the motor do not affect the capacity of the mill.

Note that the material of the blades and the body of the grinder is also very important for making the grinder. The minimum thickness of the sheets should be 2 mm. It is better to be made of food grade steel. Thin steel and iron sheets should not be used, of course, as long as the food is not in contact with the iron sheet, it is not a problem.

Having a net for separation, the possibility of joint discharge, washing, and high security are the most important features that make a mill unique. But note that it is better to buy the grinding machine from the factory.

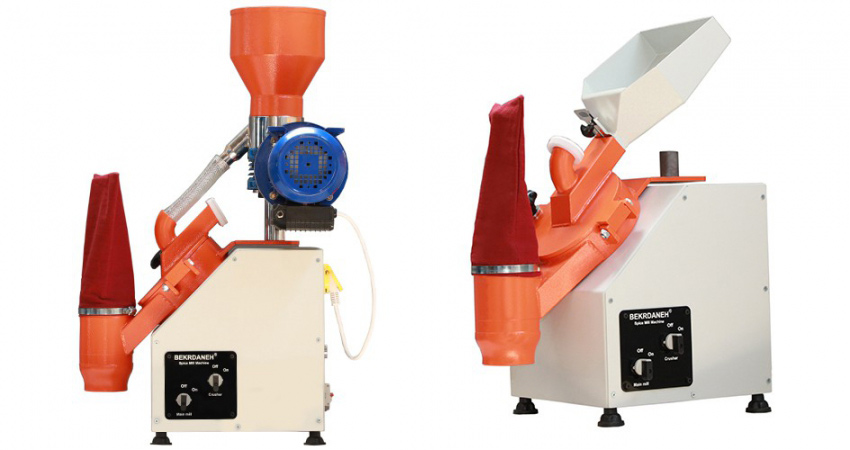

Making a spice grinder machine

One of the productions of the company is the manufacture of spice grinders. Note that the spice grinder is very sensitive. As it was said, if low-quality sheets and blades are used, corrosion and rust, etc., the device will penetrate the food.

Be sure to buy the spice grinder from a reputable company, to be sure of the excellent quality of its sheets and other products. By purchasing a spice grinder from Bekordane, in addition to the warranty, you will be taught how to use, wash and maintain the spice grinder.

Bekrdane production group produces all kinds of food and industrial machinery in a specialized manner. Excellent after-sales service, the quality of unique parts of Bekordane products has made Bekordane devices to be exported to 22 other countries besides Iran.

The company guarantees the quality of the parts and provides educational CDs and training manuals to the buyers along with the devices. Due to the unique reception of Bekordane products, in addition to opening sales offices in different provinces of Iran, sales offices have also been set up in other countries. To buy a grinding machine, you can visit the website of this collection.